Product Evaluation

What is Product Evaluation (Appearance Inspection)?

We provide evaluation services for sewn and finished products, including fabrics, fashion apparel, and accessories, manufactured in various countries such as Korea, China, Vietnam, and Indonesia. The visual inspection of sewn and finished products is primarily conducted using human sensory evaluation. Skilled inspectors perform on-site evaluations, either through complete inspections or sampling methods, to assess fabrics and finished goods.

These services support stable quality management for businesses and contribute to consumer protection and enhanced product reliability.

Key Items

Evaluations of sewn items and finished products are primarily conducted through human sensory assessments. By utilizing field visits conducted by specialized evaluators, we perform detailed appearance inspections of fabrics, completed products, and sampling. These services ensure stable quality management for businesses, enhance consumer protection, and strengthen product credibility in the market.

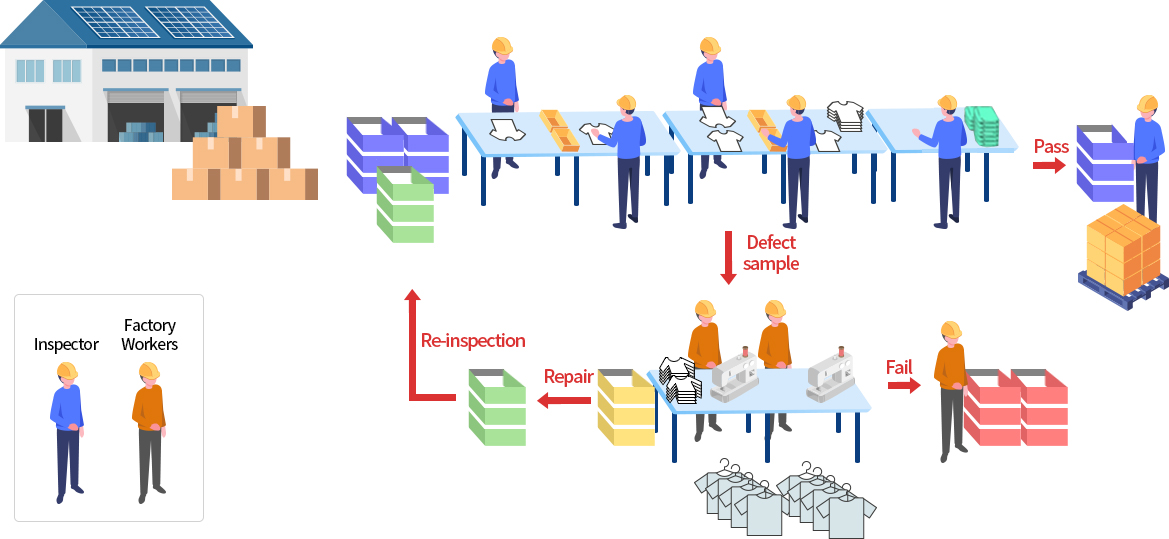

Finished Products Full Inspection

This method involves a thorough evaluation of all sewn items and finished products for appearance. Each item is individually inspected, and only those meeting the established quality standards are classified as “qualified products.”

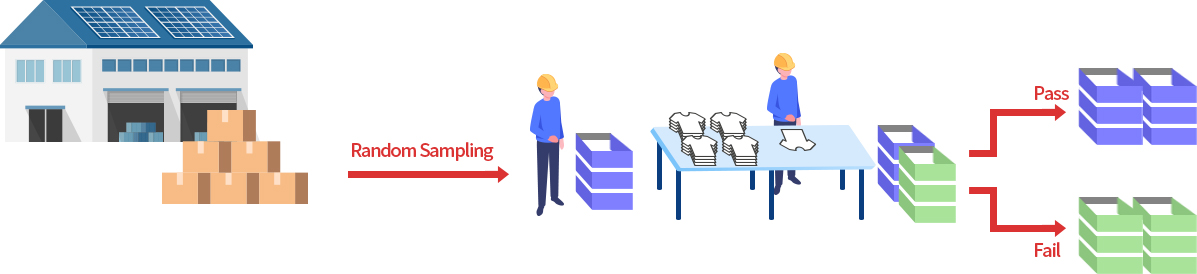

Sampling evaluations

This evaluation method involves extracting product samples from a LOT, conducting a visual inspection, and comparing the results against the criteria specified in the sampling table. Based on the findings, the LOT is determined to either pass or fail.

- The sampling quantity is determined through mutual agreement to align with AQL (Acceptable Quality Levels).

-

Basic sampling table: KS Q ISO 2859-1:1999, Normal Inspection

*Normal Inspection: Used when there is no reason to suspect that the process average differs from the AQL.

Other evaluations

Initial inspection

- This evaluation method confimrs whether "standard-compliant products" are being produced in accordance with specified requirements during the initial stages of production.

Factory evaluations

- This evaluation method involves a third-party inspection agency visiting the production site to assess factory conditions, as well as evaluate sewn items and finished products.

Overseas network status

| region | Branch/Office | Main evaluation items | Status of Evaluation Center |

|---|---|---|---|

| china | Yeontae | Clothing, bedding, miscellaneous goods | 30 people |

| Cheongdo | Clothing, bedding, miscellaneous goods | 20 people | |

| Shanghai | Clothing, bedding, miscellaneous goods ※Shanghai: Fabric evaluation possible |

30 people | |

| Dalian | 25 people | ||

| vietnam | Hanoi | Clothing, bedding, miscellaneous goods | 150 people |

| Ho Chi Minh | Clothing, bedding, miscellaneous goods | 70 people | |

| Danang | Clothing, bedding, miscellaneous goods | 30 people | |

| Indonesia | Jakarta Solo |

Clothing, bedding, miscellaneous goods | 70 people |

| Myanmar | Yangon | Clothing, bedding, miscellaneous goods | 25 people |

| Bangladesh | Taka | Clothing, bedding, miscellaneous goods | 30 people |

| Philippines | Manila | Clothing, bedding, miscellaneous goods | 10 people |

| Cambodia | Phnom Penh | Clothing, bedding, miscellaneous goods | 5 people |

| Domestic | seoul | Clothing, bedding, miscellaneous goods | 15 people |